PUFF'D

Video of Completed PUFFD Panels

COMPOSITES, SUPER COMPONENTS, & META-SEAMS

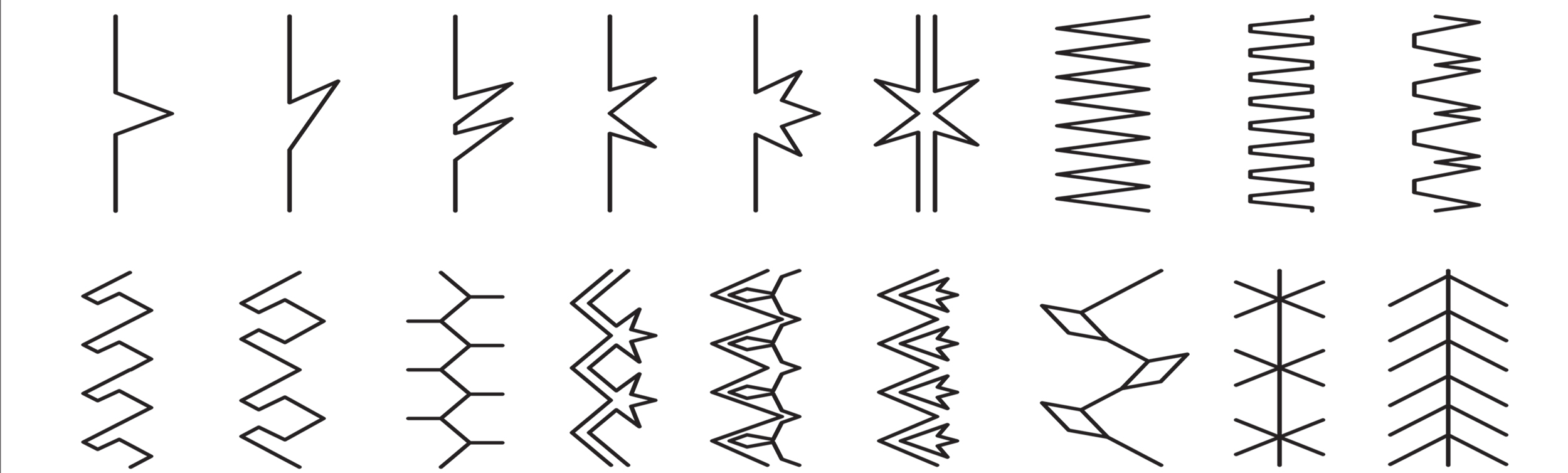

PUFF’D prototype explores plasticity of COMPOSITE construction and the role of the seam and joint in architecture. Inspired by Japanese wood joinery, puffy jackets and jet fighter airplanes, PUFF’D proposes a novel construction technique for full scale architecture. Instead of following parametric paneling and module-based logics, PUFF’D employs large monolithic building components or SUPER-COMPONENTS suggesting new ways of full scale assembly on site. The project follows up on our previous explorations including studies of super-components, joinery, material agency, and robotic assembly. The previous prototype used the language of stitching and wood joinery to study how composite tectonics would utilize a MEGA-SEAM for a simplified assembly and explored the role of real and fake

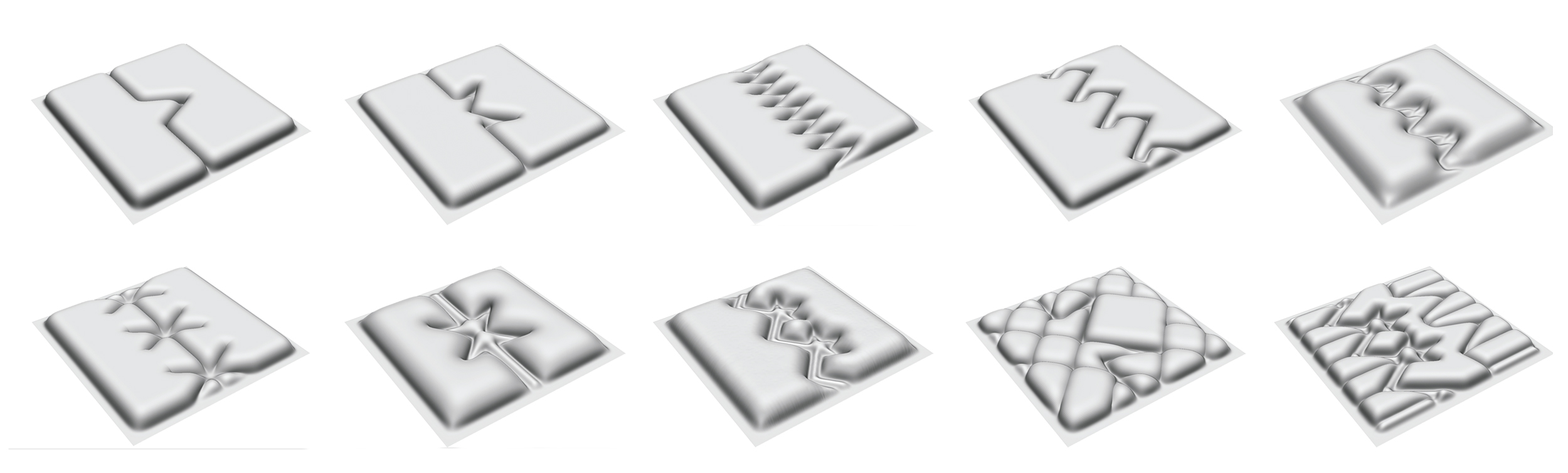

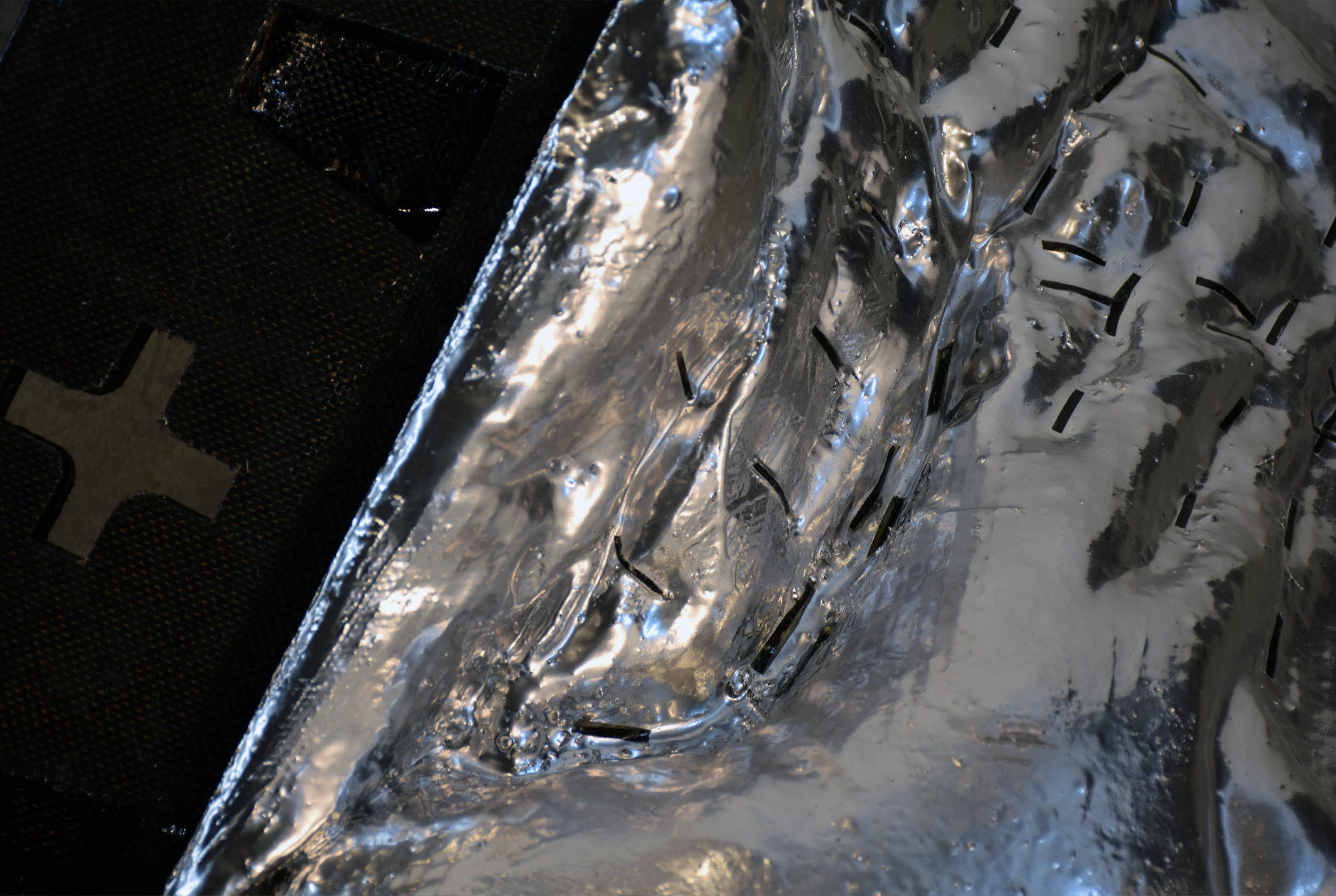

seams in architectural assemblages. The current proposal scales up and develops an inflatable composite sandwich technique to minimize waste and explore new formal and structural possibilities. PUFF’D alters the aesthetic of traditionally seen and recognized materiality and displays a structural system that appears soft in nature. Unlike current facades or shell systems the injected surface presents itself as a soft surface not recognized yet in architectural applications. A precise tectonic seam and stitching pattern encourage an inexact articulated soft surface treatment. The form of the prototype is a folded envelope with hyperbolic surfaces.

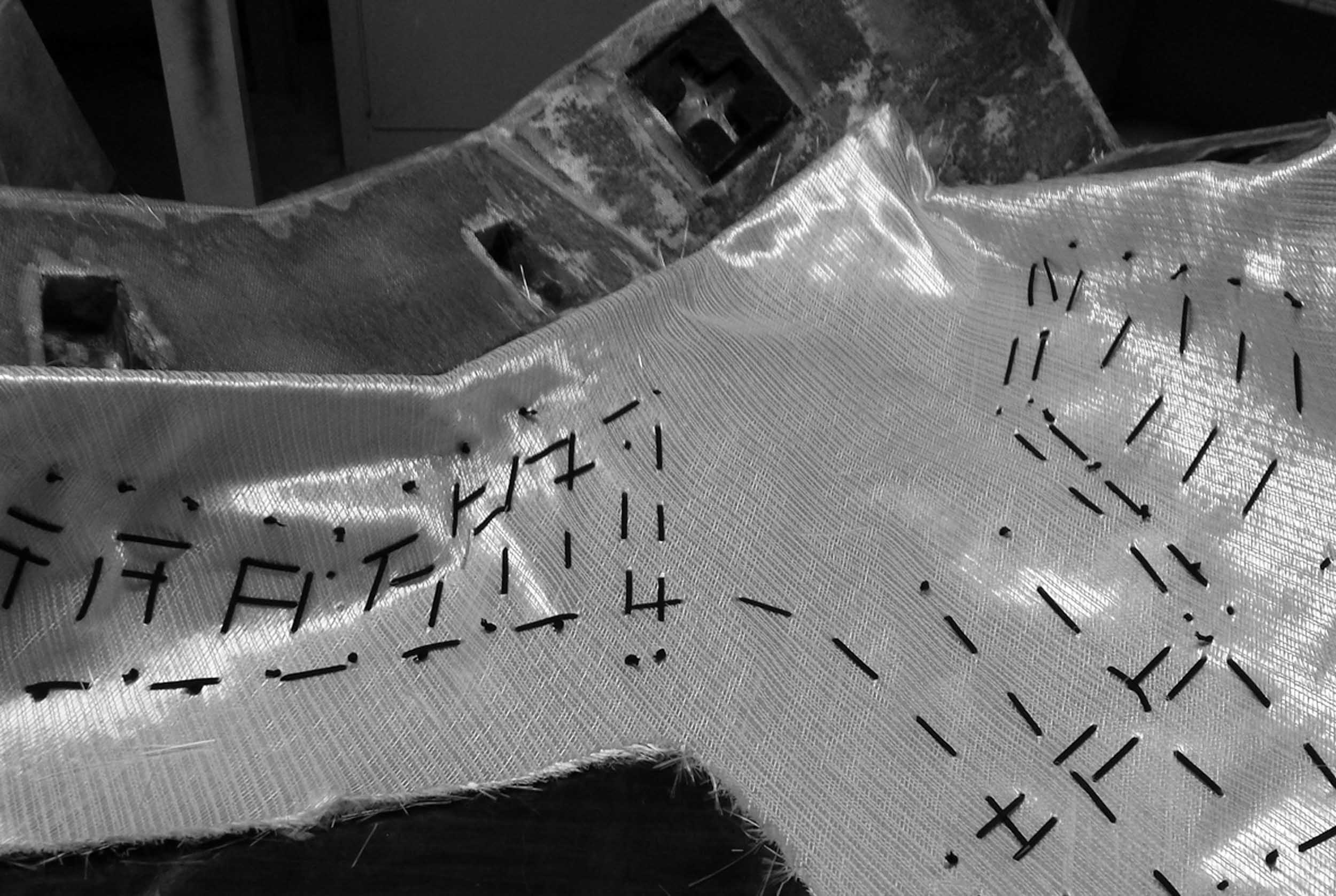

The built prototype displays the injected sandwich COMPOSITE technique with stitching patterns derived from the structural analysis of the form. Building PUFF’D is broken into the assembly of rigid joints and flexible fabric components. The joint is constructed out of carbon fiber to achieve a base rigidity to the SUPER-COMPONENT. The stitching of the fiberglass fabric was executed with stretchable thread allowing the injection of spray foam to inflate the panel system. Once completed the joint is embedded within the fabric and fastened in place via resin then injected with foam in specific volumes to area based on previous analysis. Once the panel has expanded multiple coats of resin creates a composite MONOCOQUE panel allowing a singular tectonic to connect finished panels to one another creating

a simplified on site construction process. The panels are designed with teeth to assist in assembly and minimize sheer loads but are fully fastened with a 3d printed key mechanism and specialized tool. At the pavilion scale these components can be assembled with as few as three people in under twenty minutes using only the printed hardware and tool. At a larger scale the fabrication process allows the fabric to be rolled on site and attached to the rigid rails prior to applying resin. This allows for enhanced shipping and assembly of architectural components and encourages the use of robotics to assist with the on site applications of injecting and resin application.

SCI-Arc 2014_Instructor_Tom Wiscombe

Partners_Nels Long & Nikita Troufanov